Train Toilet Waste Calculator

Calculate Waste Volume

Results

Estimated Waste Volume:

Water Usage:

Tank Emptying Frequency:

Environmental Impact:

-

-

-

-

Ever wondered what happens to the waste you flush on a moving train? train toilets aren’t just tiny rooms with a pipe; they’re a compact engineering solution that keeps the rail line clean and the environment safe. Below we break down the different toilet types, how waste travels from the carriage to a treatment plant, and what passengers can do to avoid nasty surprises.

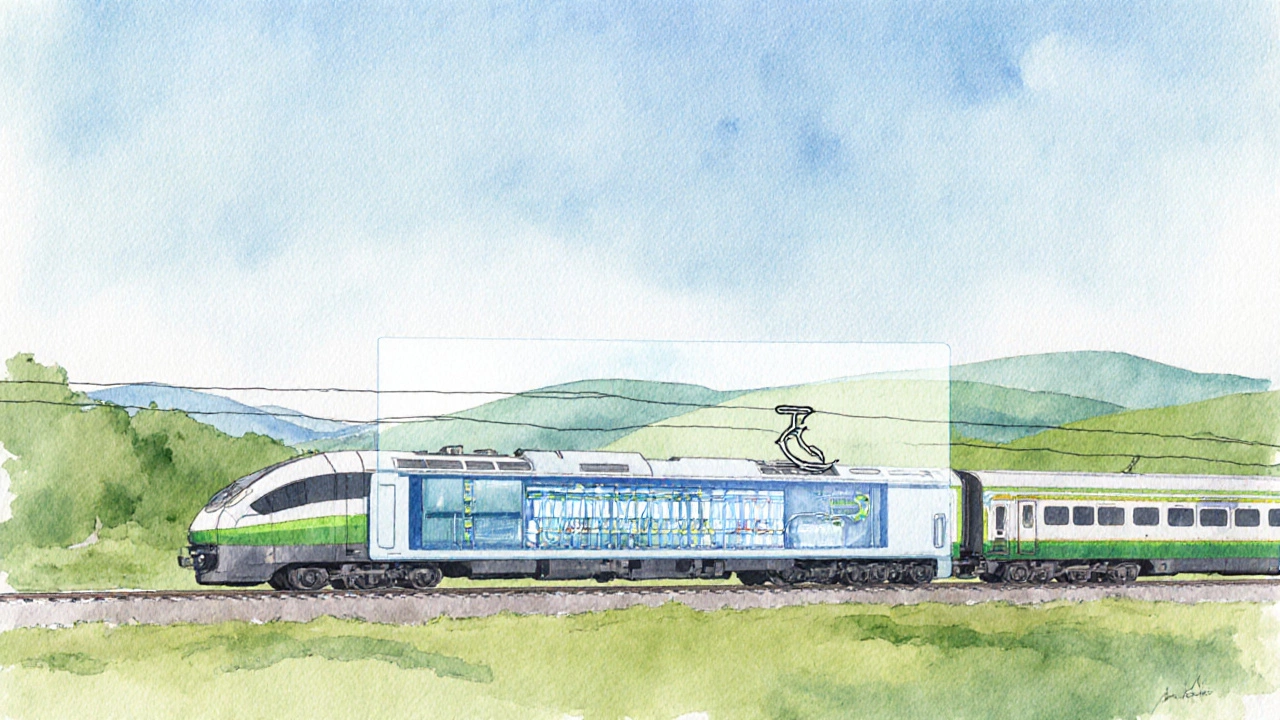

Train toilet is a sanitation fixture installed on railway coaches that collects human waste while the train is in motion, using either vacuum, chemical, or biological systems. It is a critical component of railway bathroom and is regulated by national rail authorities.Types of Train Toilets

Modern trains use four main technologies. Each has its own plumbing, waste‑handling method, and passenger experience.

| System | How It Flushes | Waste Storage | Typical Use Regions | Pros | Cons |

|---|---|---|---|---|---|

| Vacuum | Low‑pressure suction pulls waste into a sealed tank | Sealed retention tank (30‑100L) | Europe, Japan, high‑speed services | Quiet, minimal odor, low water use | Complex maintenance, requires vacuum pumps |

| Chemical | Water‑flush mixes waste with biocide | Tank with chemicals (formalin or similar) | India, older commuter trains | Simple, cheap to install | Strong smell, chemical handling hazards |

| Bio‑digester | Enzymatic breakdown digests waste on‑board | Bioreactor chamber (often 50‑150L) | Newer Indian long‑distance trains, some European prototypes | Eco‑friendly, reduces discharge frequency | Higher upfront cost, requires temperature control |

| Retention‑tank only | Gravity‑filled, no flush | Large sealed container (up to 500L) | Freight locomotives, some heritage passenger cars | Very low maintenance | No water, can be uncomfortable for passengers |

From Tank to Treatment Plant: The Waste Journey

When a train reaches a service depot or a designated discharge station, crew members connect a hose to the waste‑tank outlet. The waste is pumped into a sealed tanker truck or directly into a municipal sewage system, depending on local regulations. In many European countries, the waste is sent to specialized railway sanitation facilities that pre‑treat the water before it joins the municipal network.

Retention tank is a sealed container on a train carriage that temporarily holds human waste until it can be emptied at a service facility. The tank is typically made of stainless steel to resist corrosion.For vacuum systems, the tank is emptied via a high‑pressure air blast that pushes the waste into a receiving truck. Chemical tanks are flushed with a neutralizing solution before disposal. Bio‑digester units often have a small outlet valve that allows partially digested slurry to be emptied more easily.

Regional Differences in Train Sanitation

Not all railways use the same toilet technology. Below are snapshots of the most common setups in four key markets.

- India: Indian Railways still relies heavily on chemical toilets. Since 2017, the “Bio‑toilet” initiative has introduced enzyme‑based systems on premium and long‑haul services, cutting chemical use by 40%.

- Europe: The European Railway Agency mandates that all passenger trains operating on EU corridors use vacuum or bio‑digester toilets, limiting discharge of untreated waste on the tracks.

- United States: Amtrak’s long‑distance trains primarily use vacuum toilets, while commuter lines in the Northeast often still have older chemical units awaiting upgrades.

- Australia: NSW TrainLink’s regional services employ vacuum systems, and the occasional heritage service runs retention‑tank only units for historical authenticity.

Common Issues and Passenger Tips

Even the best‑engineered system can hiccup. Here’s what you might encounter and how to handle it.

- Odor spikes: Happens when a chemical tank is near capacity. Keep the door closed, use the provided air‑freshener, and report persistent smells to train staff.

- Water‑level warnings: Vacuum toilets flash a light when the tank is 80% full. If the light stays on, avoid flushing large amounts of paper; use a bin instead.

- Clogged flush: Typically caused by non‑flushable items. If you see a blockage, use the manual pump handle (if available) or call a conductor.

- Noise: Vacuum toilets make a brief sucking sound-normal. If the sound is continuous, it may indicate a leak; alert staff.

Pro tip: Always carry a small packet of tissue and a zip‑lock bag for personal waste. It’s a courteous backup that works on any train, old or new.

Environmental Impact and Regulations

Train toilets are a surprisingly green solution compared with car or short‑haul flight travel. Vacuum systems use less than 0.5L of water per flush, and when paired with bio‑digester technology, they can reduce the organic load entering municipal sewers by up to 30%.

Regulators such as the Environmental Protection Agency in the U.S. and the Ministry of Environment in India set limits on chemical concentrations and require regular tank inspections. Failure to comply can lead to hefty fines and service suspensions.

Environmental Protection Agency is a U.S. federal agency that enforces standards on waste discharge, including railway sanitation waste.Many rail operators are now testing water‑recycling loops that treat waste on‑board and reuse the water for flushing, further cutting the environmental footprint.

Quick Checklist for Train Bathroom Use

- Check the toilet type (signs usually show a vacuum or chemical icon).

- Use only toilet paper; avoid wipes, sanitary products, or food wrappers.

- If you see a “full‑tank” light, limit flushes and use a bin.

- Close the door firmly to keep odors contained.

- Report persistent smells or malfunctions to staff promptly.

Frequently Asked Questions

Do train toilets dump waste directly onto the tracks?

No. Modern passenger trains are required to retain waste in sealed tanks until they reach a service depot or designated discharge point. Only some very old freight cars still use open‑dump systems, and those are being phased out.

How often are train toilet tanks emptied?

Frequency varies by route and system. Vacuum tanks on high‑speed services may be emptied every 2-3 days, while chemical tanks on long‑distance Indian trains are usually serviced at major stations, roughly every 500km.

Are the chemicals in Indian train toilets harmful?

The chemicals (often formaldehyde‑based) are used to inhibit odor and bacterial growth. They are stored in sealed tanks, so exposure to passengers is minimal. However, they must be handled with protective gear by maintenance crews, and the government is encouraging a shift to bio‑digesters to reduce chemical use.

Can I bring a baby changing mat into the train bathroom?

Absolutely. Most train toilets have enough floor space for a small mat, and many operators provide hand‑washing stations nearby. Just make sure the mat doesn’t block the door or the flush controls.

What should I do if the toilet won’t flush?

Press the manual pump handle if one is present; otherwise, locate a staff member or conductor. Most trains carry a portable hand‑pump for emergencies. Avoid forcing the flush again, as that can damage the system.